"Manufacturer soundproof rooms cost at least 500,000 yen… Too expensive!" "Can’t I just buy materials from a home center and make it myself for around 100,000 yen?"

Everyone considers the path of the “Self-Made Soundproof Room (DIY)” at least once. While there are many success stories on YouTube, jumping in lightly can result in creating a “giant piece of oversized trash” in your room.

Today, I’ll explain the real performance limits and the suitability of self-made soundproof rooms without any sugar-coating.

Performance Limits of DIY Soundproof Rooms are Determined by “Gaps” and the “Door”#

Theoretical Value vs. Measured Value#

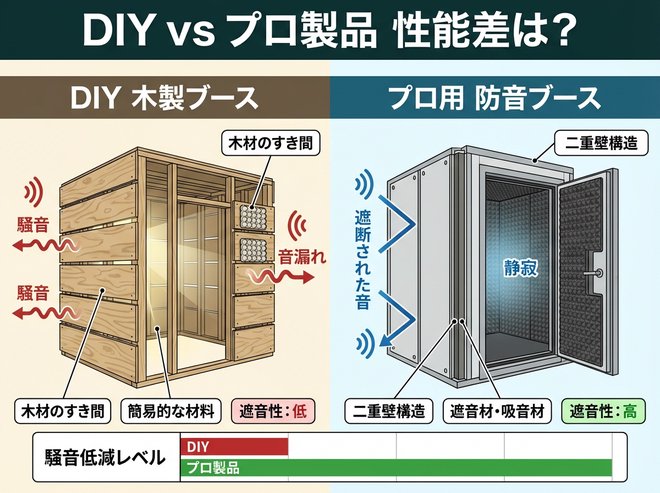

If you paste multiple layers of gypsum board and sound-insulating sheets, the sound insulation performance of the wall unit alone can reach levels comparable to professional products. This is the “Mass Law.” However, the performance of the soundproof room as a whole (Dr-value) is determined by its “weakest point.”

A 1% Gap is Fatal#

There is a terrifying law in the world of soundproofing. The fact is: “A gap of only 1% in a wall reduces sound insulation performance by 20dB.”

In amateur DIY construction, gaps of millimeter size inevitably occur at the corners of the ceiling or floor. Furthermore, the biggest hurdle is the “soundproof door.” It is extremely difficult to self-make an airtight door (using Gremon handles, etc.), and sound will leak freely from here.

As a result, the limit performance of a self-made soundproof room is around Dr-25 to Dr-30. This is a level where “human speaking voices become a bit smaller,” and it’s insufficient to stop the sound of musical instruments.

Cost: Don’t Think about Material Costs Alone#

While there are videos saying “I made it for 50,000 yen in material costs!”, don’t forget the hidden costs.

- Material Costs: Timber, gypsum board, sound-insulating sheets, and absorption materials. For a decent size, it starts at least around 100,000 yen.

- Tool Costs: Circular saw, electric screwdriver, caulking gun, etc.

- Time Cost: Designing, shopping, construction, and corrections. If you’re not used to it, a month’s worth of weekends will disappear.

- Disposal Cost: When you fail, or when you move. Dismantling and throwing away a self-made shack is harder than making it.

Who is Suited for a DIY Soundproof Room, and Who Should Avoid it?#

Suited People#

- Usage: Game streaming, telework, vocals (“Utattemita”).

- Skills: Used to woodworking and has the persistence to fill gaps with caulking.

- Environment: Detached house where family members forgive a little sound leakage.

Unsuited People (Should buy a ready-made product)#

- Usage: Drums, saxophone, trumpet, piano.

- Environment: Mansion/Apartment (Neighborhood trouble is not allowed).

- Skills: DIY beginners.

Summary: DIY is About “Romance” rather than “Cheapness”#

A self-made soundproof room is high-risk as a means of cost reduction. Buying a “Danbotchi” or a used soundproof room is often cheaper results-wise and provides reliable performance.

Nevertheless, if you have the romance of “wanting to build a secret base with my own hands!”, make up your mind and take on the challenge.