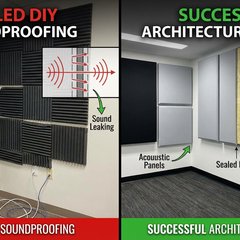

You believed the online ads that said, “Just stick these on your wall to stop noise.” You spent hundreds on acoustic foam and rubber sheets, yet the neighbor’s wall-slamming hasn’t stopped. This is the “Pattern of Despair” most common in DIY soundproofing.

Soundproofing is not a matter of intuition or “decorating.” It is a matter of “Laws of Physics.”

In this article, as an acoustic architect, I will scientifically explain why your DIY project failed and present the “Golden Ratio” that yields maximum results for minimum cost—leveraging the high-precision technology of Japanese acoustic panels.

1. The Fatal Misconception: Absorption Does NOT Block Sound#

90% of failures stem from confusing “Absorption” with “Sound Insulation (Insulation).”

- Absorption Materials (Urethane foams, felt, etc.) : Their purpose is to “manage indoor echo.” Because they are porous, sound passes right through them. Their ability to stop sound leakage is negligible.

- Insulation Materials (Rubber sheets, Gypsum board, etc.) : Their purpose is to “bounce sound back.” This requires “Mass (Weight).” Light materials cannot stop low-frequency energy.

“Reflect with insulation, then soak up the remaining energy with absorption.” If you skip this order or ratio, your performance will drop to less than half of the theoretical value.

2. The Fear of “Acoustic Short Circuits” (Sound Leaks)#

No matter how much you spend on high-end insulation, “a 1 mm gap” is enough to collapse your entire soundproofing strategy. This is known as an “Acoustic Short Circuit.”

- The Cause : Electrical outlets, door corners, and the seams between panels.

- The Reality : A gap covering only 0.1% of the surface area can reduce your insulation performance (D-value) by over 10 dB. In human terms, that means the sound sounds twice as loud.

For a successful DIY, your focus should not just be on “sticking things to the wall,” but on “sealing every gap perfectly with caulk or airtight tape.”

3. Why Japanese Soundproof Panels? The High-Performance Secret#

When rebuilding your room, look to Japanese-engineered panels (like those from Shizuyuka or Daiken). Japan’s notoriously thin-walled apartments have forced manufacturers to develop panels that are exceptionally dense yet thin.

- JIS Standard Reliability : Unlike generic foam found on massive e-commerce sites, Japanese panels are tested under JIS (Japanese Industrial Standards). You get exactly the decibel reduction promised on the label.

- Superior Cost-Performance : Because these panels are designed for modular DIY use in rental apartments, they offer the highest “performance-per-dollar” when you factor in the labor and time saved.

- Resale Value : High-quality Japanese panels maintain their shape and effectiveness for years, often fetching 30-40% of their original price on the secondhand market if you ever decide to move.

4. 3 Steps to Reconstruct Your Setup#

If your current DIY is failing, reinforce it in this order:

- Re-check Airtightness : Darken the room and see where light peaks through. If light gets in, sound gets out. This is your “Leak Path.”

- Add Mass : Overlay your insulation sheets with a layer of “Gypsum Board” or high-density soundproofing panels. Weight is the only “Truth” in acoustics.

- Layer Heterogeneous Materials : Don’t just stack the same material. Mix rubber (insulation) with wool (absorption). This “Layering of Different Densities” prevents the “Resonance” that occurs at specific frequencies.

Conclusion: Soundproofing is “Sealing,” Not “Decorating”#

You can decorate your wall with beautiful panels, but if the sound leaks, it isn’t soundproofing.

Professional acoustic architecture invests more in the “Heavy Base” and “Total Airtightness” behind the scenes than in the visible finish. What your DIY setup likely lacks isn’t expensive “magic” materials, but a strict adherence to physical laws. Start by sealing the gaps—then feel the silence.

Related Articles :